Twisted pair

Twisted pair cabling is a type of wiring in which two conductors (the forward and return conductors of a single circuit) are twisted together for the purposes of canceling out electromagnetic interference (EMI) from external sources; for instance, electromagnetic radiation from unshielded twisted pair (UTP) cables, and crosstalk between neighboring pairs. It was invented by Alexander Graham Bell and he was granted US patent 244,426 Telephone-circuit for the invention in 1881.[1]

Contents |

Explanation

In balanced pair operation, the two wires carry equal and opposite signals and the destination detects the difference between the two. This is known as differential mode transmission. Noise sources introduce signals into the wires by coupling of electric or magnetic fields and tend to couple to both wires equally. The noise thus produces a common-mode signal which is cancelled at the receiver when the difference signal is taken. This method starts to fail when the noise source is close to the signal wires; the closer wire will couple with the noise more strongly and the common-mode rejection of the receiver will fail to eliminate it. This problem is especially apparent in telecommunication cables where pairs in the same cable lie next to each other for many miles. One pair can induce crosstalk in another and it is additive along the length of the cable. Twisting the pairs counters this effect as on each half twist the wire nearest to the noise-source is exchanged. Providing the interfering source remains uniform, or nearly so, over the distance of a single twist, the induced noise will remain common-mode. Differential signaling also reduces electromagnetic radiation from the cable, along with the associated attenuation allowing for greater distance between exchanges.

The twist rate (also called pitch of the twist, usually defined in twists per meter) makes up part of the specification for a given type of cable. Where nearby pairs have equal twist rates, the same conductors of the different pairs may repeatedly lie next to each other, partially undoing the benefits of differential mode. For this reason it is commonly specified that, at least for cables containing small numbers of pairs, the twist rates must differ.

In contrast to FTP (foiled twisted pair) and STP (shielded twisted pair) cabling, UTP (unshielded twisted pair) cable is not surrounded by any shielding. It is the primary wire type for telephone usage and is very common for computer networking, especially as patch cables or temporary network connections due to the high flexibility of the cables.

History

The earliest telephones used telegraph lines, or open-wire single-wire earth return circuits. In the 1880s electric trams were installed in many cities, which induced noise into these circuits. Lawsuits being unavailing, the telephone companies converted to balanced circuits, which had the incidental benefit of reducing attenuation, hence increasing range.

As electrical power distribution became more commonplace, this measure proved inadequate. Two wires, strung on either side of cross bars on utility poles, shared the route with electrical power lines. Within a few years the growing use of electricity again brought an increase of interference, so engineers devised a method called wire transposition, to cancel out the interference. In wire transposition, the wires exchange position once every several poles. In this way, the two wires would receive similar EMI from power lines. This represented an early implementation of twisting, with a twist rate of about four twists per kilometre, or six per mile. Such open-wire balanced lines with periodic transpositions still survives today in some rural areas.

Unshielded twisted pair (UTP)

Twisted pair cables were first used in telephone systems by Alexander Graham Bell in 1881. By 1900, the entire American telephone line network was either twisted pair or open wire with similar arrangements to guard against interference. Today, most of the millions of kilometres of twisted pairs in the world are outdoor landlines, owned by telephone companies, used for voice service, and only handled or even seen by telephone workers.

UTP cables are found in many Ethernet networks and telephone systems. For indoor telephone applications, UTP is often grouped into sets of 25 pairs according to a standard 25-pair color code originally developed by AT&T. A typical subset of these colors (white/blue, blue/white, white/orange, orange/white) shows up in most UTP cables.

For urban outdoor telephone cables containing hundreds or thousands of pairs, the cable is divided into smaller but identical bundles. Each bundle consists of twisted pairs that have different twist rates. The bundles are in turn twisted together to make up the cable. Pairs having the same twist rate within the cable can still experience some degree of crosstalk. Wire pairs are selected carefully to minimize crosstalk within a large cable.

UTP cable is also the most common cable used in computer networking. Modern Ethernet, the most common data networking standard, utilizes UTP cables. Twisted pair cabling is often used in data networks for short and medium length connections because of its relatively lower costs compared to optical fiber and coaxial cable.

UTP is also finding increasing use in video applications, primarily in security cameras. Many middle to high-end cameras include a UTP output with setscrew terminals. This is made possible by the fact that UTP cable bandwidth has improved to match the baseband of television signals. While the video recorder most likely still has unbalanced BNC connectors for standard coaxial cable, a balun is used to convert from 100-ohm balanced UTP to 75-ohm unbalanced. A balun can also be used at the camera end for ones without a UTP output. Only one pair is necessary for each video signal.

Cable shielding

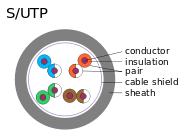

Twisted pair cables are often shielded in attempt to prevent electromagnetic interference. Because the shielding is made of metal, it may also serve as a ground. However, usually a shielded or a screened twisted pair cable has a special grounding wire added called a drain wire. This shielding can be applied to individual pairs, or to the collection of pairs. When shielding is applied to the collection of pairs, this is referred to as screening. The shielding must be grounded for the shielding to work.

- Shielded twisted pair (STP or STP-A)

- STP cabling includes metal shielding over each individual pair of copper wires. This type of shielding protects cable from external EMI (electromagnetic interferences). e.g. the 150 ohm shielded twisted pair cables defined by the IBM Cabling System specifications and used with token ring networks.

- Screened unshielded twisted pair (S/UTP)

- Also known as Foiled Twisted Pair (FTP), is a screened UTP cable (ScTP).

- Screened shielded twisted pair (S/STP or S/FTP)

- S/STP cabling, also known as Screened Fully shielded Twisted Pair (S/FTP), [2] is both individually shielded (like STP cabling) and also has an outer metal shielding covering the entire group of shielded copper pairs (like S/UTP). This type of cabling offers the best protection from interference from external sources, and also eliminates alien crosstalk[2].

Note that different vendors and authors use different terminology (i.e. STP has been used to denote both STP-A, S/STP, and S/UTP) [3].

Solid core cable vs stranded cable

Solid core cable is supposed to be used for permanently installed runs. It is less flexible than stranded cable and is more prone to failure if repeatedly flexed. Stranded cable is used for fly leads at patch panel and for connections from wall-ports to end devices, as it resists cracking of the conductors. Stranded core is generally more expensive than solid core.

Connectors need to be designed differently for solid core than for stranded. Use of a connector with the wrong cable type is likely to lead to unreliable cabling. Plugs designed for solid and stranded core are readily available, and some vendors even offer plugs designed for use with both types. The punch-down blocks on patch-panel and wall port jacks are designed for use with solid core cable.

Manufacture

- Copper Rod Breakdown

- The first step in low voltage cable production is copper rod breakdown. Copper is sent to the factory in 5,000 lb coils. These copper coils are continuously drawn through diamond dies that drastically reduce the diameter of the copper to 10 or 12 gauge. Lubrication is used during this process to reduce the amount of friction and heat on the copper cable. Once completed, the copper is stacked in vertical coils, called stem packs. These stem packs are then transferred to another drawing operation that further reduces the gauge of the copper. During this stage, the copper is also charged with an electrical current. This anneals the copper, which is a softening process. Once annealed and cooled off, the copper runs through a laser measurement system, to verify it is within manufacturing specifications.

- Copper Insulation Process

- The copper insulation process is continually monitored and controlled up to +/- .0001". Once the copper is insulated, it runs through a water cooling trough, allowing the wire jacket to harden properly.

- Copper Twisting

- Twisting helps reduce crosstalk between the individual pairs of wire. Some Cat6 premises cables include a center spline, or wire separator, to further reduce crosstalk and increase performance. Copper twisting is accomplished by running each individual wire through multiple faceplates. This helps control pair position. Once twisted, this is known as a cable unit.

- Jacketing

- The cable unit then goes through the jacketing process. This step varies, depending on the type of cable being manufactured. OSP cable typically uses a black polyethylene or UV rated polyvinyl chloride (PVC). For Cat3, Cat5e and Cat6 premises cable, varying grades of PVC are used, depending on flame safety rating requirements. This step starts off with molten plastic being extruded at high pressure and formed around the moving cable core. Shielding, ripcords, armoring and water blocking compound may also be applied at this step. Cables that require dual shielding or double armor will need to repeat this process. Once completed, the cable passed through a long cooling bath, then through a laser micrometer to verify the final diameter.

- Printing

- Printing is done just before the cable is put in its final packaging. For OSP cable, a hot foil printing process is used, that leaves an indented print in the cable jacket. For premises cable, a high speed ink jet printer is used. Some cable manufacturers print footage marking from 1000–0 ft, making it very easy to determine how much cable is left in the box, or for measuring out cable runs. Other manufacturers use a six digit footage mark, making the process a little harder.

- Coiling

- The completed cable is then wound onto a reel or coil. The coiling process requires very precise tension controls to ensure the cable won't tangle when being pulled out of its box.

- Final Testing

- Once the cable is printed and coiled, it goes through one last set of tests. The manufacturer will test it against a large set of mechanical and electrical performance specifications. Once tested, the cable is ready for shipment.

Advantages

- It is a thin, flexible cable that is easy to string between walls.

- More lines can be run through the same wiring ducts.

- UTP costs less per meter/foot than any other type of LAN cable.

Disadvantages

- Twisted pair’s susceptibility to electromagnetic interference greatly depends on the pair twisting schemes (usually patented by the manufacturers) staying intact during the installation. As a result, twisted pair cables usually have stringent requirements for maximum pulling tension as well as minimum bend radius. This relative fragility of twisted pair cables makes the installation practices an important part of ensuring the cable’s performance.

- In video applications that send information across multiple parallel signal wires, twisted pair cabling can introduce signaling delays known as skew which results in subtle color defects and ghosting due to the image components not aligning correctly when recombined in the display device. The skew occurs because twisted pairs within the same cable often use a different number of twists per meter so as to prevent common-mode crosstalk between pairs with identical numbers of twists. The skew can be compensated by varying the length of pairs in the termination box, so as to introduce delay lines that take up the slack between shorter and longer pairs, though the precise lengths required are difficult to calculate and vary depending on the overall cable length.

Minor twisted pair variants

- Loaded twisted pair: A twisted pair that has intentionally added inductance, common practice on telecommunication lines, except those carrying higher than voiceband frequencies. The added inductors are known as load coils and reduce distortion.

- Unloaded twisted pair: A twisted pair that has no added load coils.

- Bonded twisted pair: A twisted pair variant in which the pairs are individually bonded to increase robustness of the cable. Pioneered by Belden, it means the electrical specifications of the cable are maintained despite rough handling.

- Twisted ribbon cable: A variant of standard ribbon cable in which adjacent pairs of conductors are bonded and twisted together. The twisted pairs are then lightly bonded to each other in a ribbon format. Periodically along the ribbon there are short sections with no twisting to enable connectors and pcb headers to be terminated using the usual ribbon cable IDC techniques.

See also

- Balanced line

- Tip and ring

- Ethernet over twisted pair

- Registered jack

- TIA/EIA-568-B

- Category 5 cable

- Litz wire

References

- ↑ US 244426, Bell, Alexander Graham, "Telephone-circuit", issued 1881. See also TIFF format scans for USPTO 00244426

- ↑ 2.0 2.1 Grounding for Screened and Shielded Network Cabling - Siemon

- ↑ Anitech Systems MP 4000 Manual

External links

|

||||||||